Track Racing & Track Days

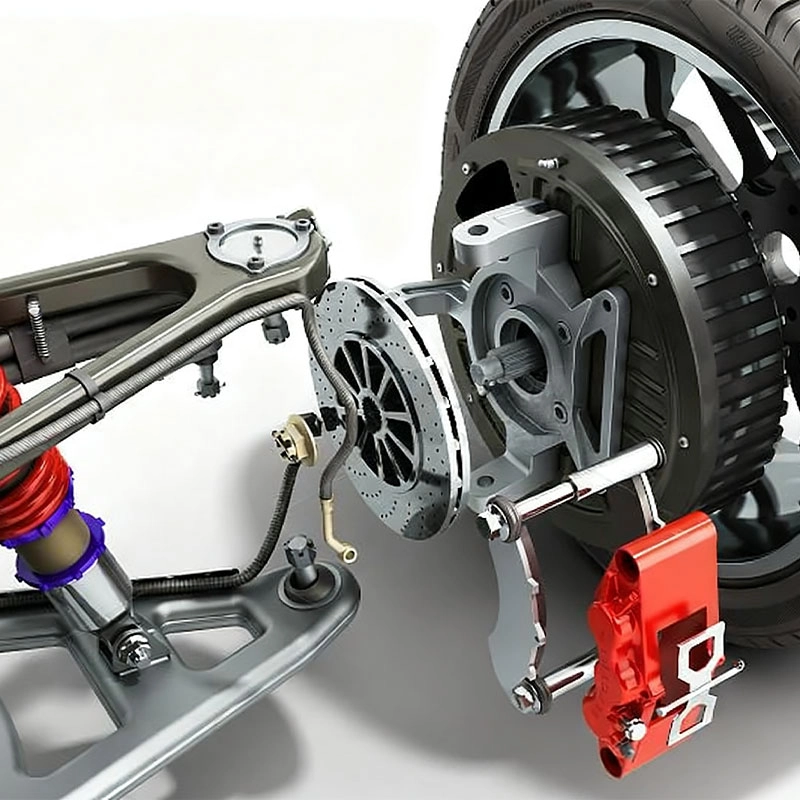

For professional racing and track day vehicles in the high-intensity and demanding environment of the track, ICOOH provides high-temperature-resistant, lightweight, stable, and reliable braking system solutions, enabling every extreme maneuver.

Core Pain Points for Racing Users

-

Frequency, High-Intensity Braking: Continuous hard braking and ultra-high speeds can easily cause stock brakes to fade.

High-Temperature Resistance & Stability: Maintaining a stable friction coefficient even at temperatures exceeding 600°C.

Weight Sensitivity: Every kilogram matters in acceleration, braking, and cornering performance.

Quick Maintenance and Replacement: Brake pads, discs, or calipers must be quickly replaced during a race.

Compliance with Competition Standards: Must meet CE, ISO, and other certifications.

ICOOH High-Performance Racing Braking System Solutions

Recommended Case Studies

Why Racing Teams Choose ICOOH

1 -

Professional Manufacturing

We utilize our own factory and high-precision molds, specializing in racing-grade carbon fiber and alloy brake systems.

2 -

Extreme Testing

All products are tested on the track under high-temperature, high-speed, and high-frequency conditions.

3 -

Lightweight & High Rigidity

Every gram counts for performance.

4 -

Customization

We offer OEM/ODM solutions tailored to specific vehicle types, tracks, and driving styles.

5 -

International Certifications

We comply with CE and ISO/TS16949 and include comprehensive certification reports.

6 -

Full Technical Support

We provide installation training, track maintenance guidance, and spare parts supply.

From Requirements to Delivery, Hassle-Free, One-Stop Service

FAQs

Racing Vehicles

How long can the product maintain stable performance at high temperatures?

Tests have shown that it can maintain a stable friction coefficient continuously at temperatures of 600–800°C, with no noticeable degradation.

Can you provide test data or performance curves?

We can provide friction coefficient curves, heat resistance life test reports, braking distance data, and more.

Is replacement or maintenance easy?

The modular quick-release design allows for rapid on-track brake pad/disc replacement, minimizing downtime.

How much weight is reduced compared to the stock system?

Depending on the vehicle type, it can be reduced by 20-40%, significantly improving acceleration and handling.

What are the after-sales and warranty policies?

We offer a 12-24 month warranty (depending on the product series), along with on-track technical consultants and fast spare parts support.

Ready to upgrade your racing car tuning system?

Facebook

Linkedin

Youtube

Instagram